Support strong Canadian climate journalism for 2025

The clock was ticking last spring. A multinational Texas-based energy company had only a few days left to comply with an emergency safety order, issued in February 2016 by Canada’s National Energy Board, which had found unsafe parts being used in pipelines.

It was now late in March and the pipeline company, Kinder Morgan, hadn’t been able to track where it had installed the potentially dangerous parts. Kinder Morgan was already under intense public scrutiny over its proposal to add a second pipeline expanding its capacity to move crude from the Alberta oilsands to a port on B.C.’s west coast.

So Kinder Morgan took what one expert calls the “Canadian approach” to industry oversight — the company called their contact at the regulator, someone who had previously asked them for a favour. And the NEB gave Kinder Morgan an additional six months to respond to the emergency safety order.

The NEB had issued the order in February because its engineers believed there was a risk of failures on a number of pipelines. Internal emails show that the engineers were concerned that multiple companies were installing substandard or defective fittings on pipeline infrastructure due to a poor safety culture and inadequate inspections by industry.

A "concerning development"

The engineers presented their case to the Board in a December 2015 memo.

“Over a number of years, there have been multiple instances of pipe and components found to have substandard material properties on pipeline systems in Canada and the US,” NEB pipeline engineering experts told the Board in the internal memo, dated Dec. 17, 2015.

“In some cases, these pipeline systems have had failures at the pressure test stage or while operating… The failures and expansions of pipe and fittings is a concerning development, as there have been advancements in material science over time including the quality control of steel production and pipe and fitting manufacture.”

It would take the NEB until Feb. 5, 2016 to take action, issuing the emergency order which gave each pipeline company 60 days to review records and come clean if they discovered problems.

National Observer has learned that Kinder Morgan was able to “walk around” this safety order, getting its six month extension by placing a phone call to the regulator a few days before the deadline.

A Kinder Morgan official told the NEB that the company would need the extension to assess its infrastructure.

“I received a call from Kinder Canada,” wrote the regulator’s technical specialist Doug Ochitwa, in a March 30 email that was sent to five coworkers with pipeline engineering and safety expertise. ”They will be seeking a 6 month variance.”

The six month extension, granted a few days later, allowed Kinder Morgan to avoid negative publicity about its safety record in the sensitive period leading up to the NEB’s May 2016 announcement recommending the federal government approve the company’s plan to expand Trans Mountain which runs from Alberta to the west coast.

Both the regulator and the company say that this expansion, a proposed tripling of the pipeline’s capacity to 890,000 barrels of oil per day, can be done safely. But a vocal opposition of local Indigenous people, mayors and environmental groups disagree. They say that the plan would lead to oil spills and prevent Canada from meeting its climate change goals.

Prime Minister Justin Trudeau’s government has given itself until December to make a final decision.

But several legal and engineering experts contacted by National Observer are skeptical about whether the regulator can be trusted to oversee this project. They say that all signs indicate that Canada’s energy regulator has been “captured” by industry.

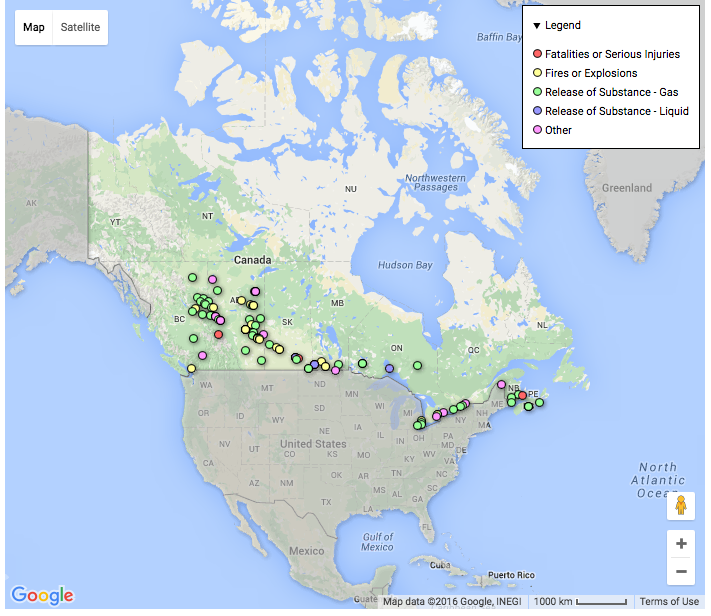

And a large trove of the NEB’s internal emails, memos and text messages reviewed by National Observer from various sources confirm the experts’ concerns that the energy regulator is doing a bad job of cracking down on the types of problems that can lead to catastrophic failures that threaten public health, safety and the environment.

Among some of the surprising revelations:

- Sloppy paperwork — The NEB has uncovered errors in the documentation provided by companies, including sloppy paperwork that incorrectly identified substandard parts on a TransCanada pipeline that blew up in 2013. The paperwork “was never verified by the company or manufacturer,” NEB engineering experts said in an internal memo sent to members of the Board last December. (TransCanada has noted that a federal investigation determined the fittings were "not the direct cause" of the incident. The company also says that the fittings that were put into service had passed safety tests)

- Missing documents — After the February safety order was issued, companies were having trouble locating their own records and approached one of their manufacturers for help.

- A conflict of interest —The NEB technical specialist who took the call from Kinder Morgan requesting the six-month extension had previously asked his contact at the company whether it could hire someone he knew who was searching for a job. Kinder Morgan never delivered on that job request, but the NEB granted the six-month extension.

Eight months to file report

Under Canadian law, anyone who violates an order from the pipeline regulator can face a five-year prison sentence and fines of up to a million dollars.

Federal rules require energy companies to keep detailed records about their pipelines and operations so that they can respond to orders like this one in a timely fashion.

But it took Kinder Morgan nearly eight months after the original safety order to file its paperwork. By then, it was already the end of September. It reported that over the past decade, it had installed 173 parts on the existing Trans Mountain pipeline that were manufactured in Thailand by Canadoil Asia, a company that underwent bankruptcy restructuring in April 2014.

This total includes 57 fittings from the manufacturer that were installed at an Edmonton terminal of the Trans Mountain pipeline.

Dodgy pipeline fittings

Canadoil Asia’s products have a history of problems. Its fittings failed during pressure tests on TransCanada Corp.'s Keystone pipeline which runs from Hardisty, Alberta to Cushing, Oklahoma. The material wasn’t as tough as it was supposed to be, so the company replaced some of the fittings and reinforced others with a special armour pipe wrap to strengthen its integrity and prevent a failure.

As for Kinder Morgan, the report it submitted to the NEB at the end of September indicated that it had misplaced some paperwork and could not find the purchase orders for two of the pipeline fittings it reviewed. Yet it concluded, nonetheless, that all of the parts made by Canadoil Asia on its Trans Mountain pipeline were satisfactory.

A spokesperson for the NEB told National Observer that the regulator is reviewing Kinder Morgan's paperwork, submitted on Sept. 29, and was not immediately able to comment on Kinder Morgan's analysis. At least one independent engineer says the assessment wasn’t thorough enough to determine whether the infrastructure is safe, while Kinder Morgan says it has complied with the order.

NEB in a tight spot

But whenever problems like these arise, most industry insiders say that serious punishments, such as steep fines or jail time, are almost unheard of in the pipeline industry. Industry lobbyists and representatives from the regulator downplay safety concerns, noting that their statistics show that pipelines safely deliver more than 99 per cent of the fossil fuels they carry.

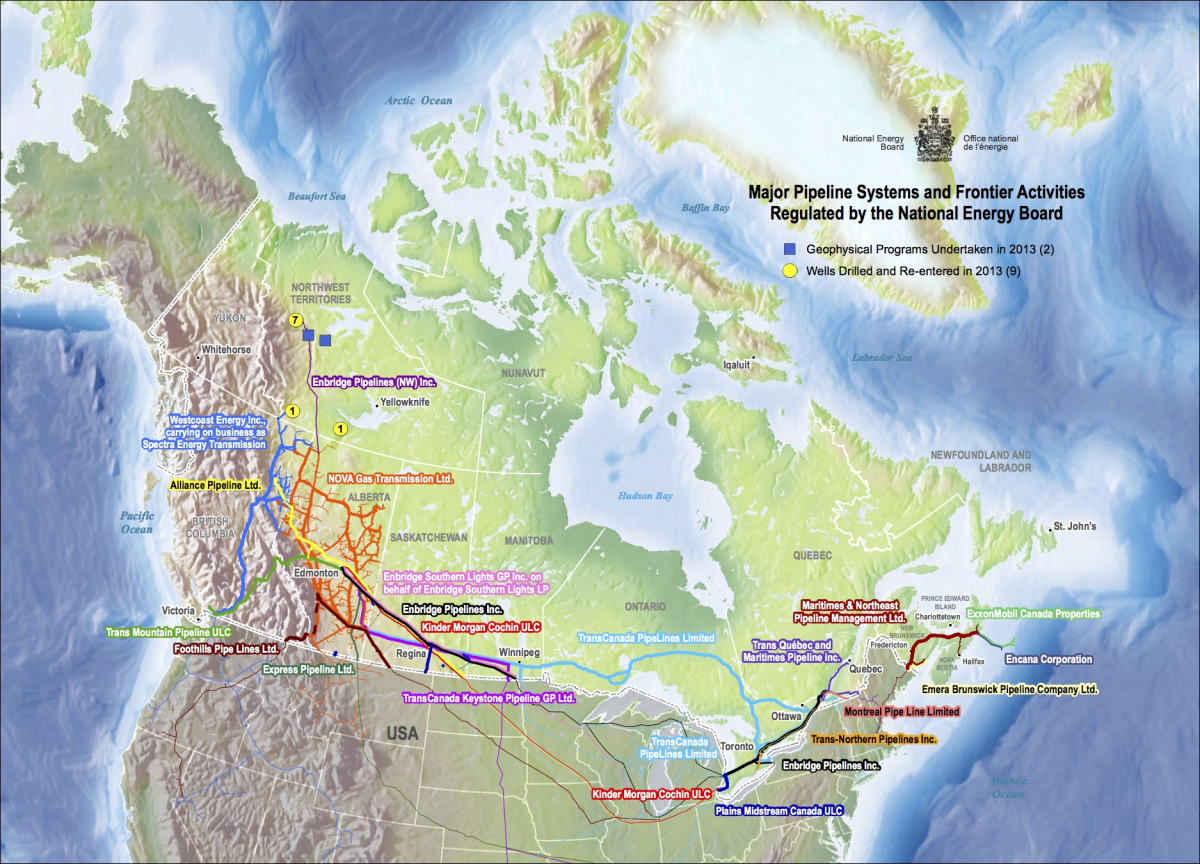

Keystone and Trans Mountain are among a series of pipelines that provide an export route out of Canada for the country’s oilsands industry in Alberta. The oil producers have been hammered in recent years by slumping global commodity prices and are desperate to reach new markets and customers. Any safety shutdown or pressure restrictions on these pipelines could affect struggling oil producers already shouldering high production costs due to massive amounts of energy and water needed to extract the bitumen — a heavy tar-like oil.

This puts the Canadian pipeline regulator in a tight spot. The NEB must enforce standards while also facing pressure to protect the economic viability of an industry that employs seven per cent of Alberta's workforce.

When the NEB takes enforcement action, it can drive up costs for pipeline operators and the oil companies that are paying to ship the oil. Industry insiders speculate that this leads the regulator to go easy on pipeline companies, treating them as customers instead of adequately protecting public safety.

"Walkaround" the safety order

The Canadian regulator has extraordinary powers under Canadian law to investigate any matter under its jurisdiction and compel parties to release evidence. The law also gives the NEB the powers of a federal court and, as a result, it is required to ensure transparency and openness in all of its dealings with industry.

But contrary to its own rules, the NEB’s internal emails reveal that it conducts off-the-record discussions with several companies about regulatory and safety matters. That’s what happened with the largest pipeline company in Canada, Enbridge Inc., when it asked for its own 120-day extension on the safety order.

“Based on conversations I have had with some of you, I have indicated in conversations with Enbridge that we would consider this request,” wrote NEB engineer Susan Bouzane, in an email sent to other NEB staff on March 30. “I am just not sure what the process is for a variance to a general order.”

One week later, Bouzane sent out what she would call a “Walkaround” memo, in consultation with Doug Ochitwa — the employee who took the call from Kinder Morgan — and other NEB staff, that recommended the approval of the Texas company’s unusual request for a six-month extension.

“This is a significant amount of time, however keep in mind that in Enbridge’s extension, they also stated that they may need additional time (on top of their already granted extension) as they get further into the review,” she wrote in an April 6 email as she shared the “Walkaround” memo.

The NEB and the industry tell National Observer that informal discussions are “normal,” and a “part of doing business.”

Ochitwa’s other communications with Kinder Morgan reveal a pleasant and convenient relationship between the regulator and the industry.

"Help me possibly help Kinder Morgan"

In 2014, a former TransCanada employee came forward with serious safety allegations against that company after losing his job — allegations that would be partially substantiated by the NEB but then largely dismissed a year later. Just as it received the allegations, Ochitwa, the NEB technical pipeline safety specialist, sent emails to a Kinder Morgan Canada official praising the whistleblower's expertise and recommending the former TransCanada employee for a job.

This request by Ochitwa came after the Kinder Morgan official provided him with advance notice about a regulatory request that the company was about to make to the NEB.

“Thanks for the heads up!” Ochitwa wrote in an email to his contact on Sept. 9, 2014. “As an aside, I wonder if you could help me possibly help Kinder Morgan. We had a guy inquire about working at the Board (as an inspector). We’re not able to immediately help him. Still, he has a lot of field experience in all aspects of pipeline construction and maintenance.”

This email was released through access to information by the NEB, which censored the name of the Kinder Morgan employee who was corresponding with Ochitwa. But on the same day he sent this message, Ochitwa also sent the whistleblower a text message to connect him with Megan Sartore, a senior regulatory advisor in Canada for Kinder Morgan.

Ochitwa told the whistleblower in this message not to tell Sartore the entire truth about how he got in contact with the NEB and his experience at TransCanada Pipelines Limited (TCPL).

“This is Doug,” he wrote in the text message to the whistleblower. “Call Megan Sartore at Kinder Morgan at 403-xxx-xxxx about that job. I said nothing about TCPL. Don’t say anything either. I simply said you applied for an inspector position at the Board.”

Sartore is the same person who signed Kinder Morgan’s formal request for an extension in April and its latest submission to the Board in September. The NEB and Kinder Morgan declined to say whether she was also the same person who spoke to Ochitwa over the phone and exchanged emails with him.

Ochitwa didn't respond to a request for comment.

"It could be viewed as influence peddling. That's not appropriate bud!"

Kinder Morgan also declined to comment on Ochitwa’s job request exchange with her company, saying only that discussions on regulatory matters were normal.

“As part of doing business, Kinder Morgan Canada employees communicate with National Energy Board staff,” said Kinder Morgan spokeswoman Lisa Clement. “It is normal practice for a company to provide notice, in advance, advising the NEB of an upcoming filing.”

The TransCanada whistleblower has alleged that Ochitwa wasn’t acting alone when he reached out to Kinder Morgan and that the efforts to help him find work with other companies regulated by the NEB were approved by a senior NEB manager, the regulator’s vice-president of operations, Chris Loewen. Other internal emails and text messages viewed by National Observer confirm that other NEB staff were in the loop about Ochitwa’s actions.

Ochitwa himself also recognized that he had to be careful, when he was pressed by the whistleblower to follow up with the company.

"If you have concerns then you need to speak with Kinder," Ochitwa wrote in a text message on Oct. 1. "Given I'm a regulator, short of an introduction, it could be viewed as influence peddling. That's not appropriate bud!"

Enbridge and Canadoil Asia

In another example of the emails obtained by National Observer, a representative from the Canadoil Group, a company which is still manufacturing pipeline components after the bankruptcy restructuring of Canadoil Asia, urged the NEB to go easy on its customers.

“We have been approached by a number of distributors and pipeline companies regarding the NEB order,” wrote a Canadoil representative in a March 16, 2016 email to Bouzane, the NEB engineer. “Everyone is racing to meet the NEB deadline, but folks are indicating that the task is being greatly complicated by the request to identify ‘any fitting’ manufactured by Canadoil Asia.”

The Canadoil representative asked the NEB to eliminate an entire category of fittings from its safety order. Bouzane rejected that request, but invited the manufacturer to encourage its customers to ask for extensions on the deadline.

“Since Canadaoil Asia was no longer in business when the NEB was looking into this issue, we were not able to discuss this issue directly with the manufacturer,” Bouzane wrote in response to the Canadoil representative on March 21, sending copies of her email to several NEB employees, including the regulator’s chief engineer Iain Colquhoun.

In the same email, Bouzane went on to write that the NEB’s evidence suggested the safety order should cover all of the Canadoil Asia parts that were manufactured in Thailand. There was no reason to reduce this wide scope, she wrote.

“Currently, the NEB has no basis to set constraints on the fittings to be investigated, other than being manufactured by Canadoil Asia, and installed on an NEB regulated pipeline/facility,” she said, in the same email to the Canadoil Group.

“Please be advised that if you are working with customers who are unable to meet the deadline as written in the order, they are able to request an extension from the Board as our goal is to ensure we receive complete, quality information.”

“Systemic, pernicious” problem say independent experts

Several legal and engineering experts say that this type of communication demonstrates that the NEB doesn’t act as a regulator but in service to industry and needs a major overhaul to its culture and practices.

Jocelyn Stacey, an assistant professor at the University of British Columbia's Allard School of Law, who also has expertise on regulatory issues in the natural resources sector, said the job request by Ochitwa was inappropriate. She explained that it reflects what she describes as a “systemic, pernicious, institutional problem,” plaguing the NEB.

“This is clear evidence of agency capture, the situation in which the regulator serves the regulator industry rather than the public interest,” she told National Observer in an email interview. “The new evidence of agency capture illuminates how all the ordinary public accountability mechanisms have failed in the case of the NEB. Canada’s specialized environmental auditor (the commissioner of environment and sustainable development) has reported to Parliament on the systemic failures of the NEB to ensure compliance and this has failed to lead to change; a new federal government, after the NEB was an election issue, has failed to lead to institutional change.”

Prime Minister Justin Trudeau's Liberal party campaigned in the 2015 election to modernize the NEB as part of a plan to restore public confidence in major natural resources projects — now a major roadblock to growth in Canada's energy sector. But Trudeau's government is still reviewing how to deliver on that promise.

The NEB declined to answer a series of questions from National Observer about whether its employees had broken any rules. Instead, it provided a general response that summarized the expertise and the role of the members of its workforce, while noting that they were "bound-by, and take pride-in, their commitment to the values and ethics code of the public sector."

When pressed with nine additional follow up questions about the specific interactions that its technical staff had with Kinder Morgan, the NEB responded with a two paragraph statement:

"NEB technical staff are expected to have interaction with pipeline companies. Regular dialogue with companies is part of how regulators assure pipeline safety in Canada. NEB staff continue to apply extensive technical expertise in the interest of Canadian pipeline safety and environmental protection," said NEB spokesman Darin Barter in an email sent on Friday.

"We have addressed your questions regarding NEB staff on numerous occasions and ask that you refer you to the Association of Professional Engineers and Geoscientists of Alberta (APEGA) announcement that exonerated NEB staff following a 16 month investigative review of claims made against NEB staff members."

Ochitwa is not an engineer and he was not a subject of the APEGA investigation.

Meanwhile, back at the “emergency safety order”

The public might well wonder what’s happening on the emergency safety order, almost a year after the problem was formally identified.

Kinder Morgan Canada has submitted an independent engineering assessment that suggests the parts present no risk, although the engineering firm that produced the report included a disclaimer that suggested it might be wrong. The NEB has Kinder Morgan’s assessment under consideration.

Enbridge has said it has identified more than 100 Canadoil Asia fittings in its system and determined that they are safe, but is still completing an engineering assessment of potentially affected areas of its system. That report is expected before the end of October.

The NEB, in its internal memo, said the problem of substandard parts in pipelines is widespread, implicating several manufacturers from India, Mexico and Ukraine, in addition to the supplier in Thailand. The safety order did not address any of the other manufacturers, apart from a Quebec company, Ezeflow, that had supplied the parts on a TransCanada pipeline that blew up. But the order required companies to assess and mitigate all substandard parts in their systems.

Ezeflow, which is featured in advertising by an oil and gas lobby group that promotes the economic benefits of the oilsands industry, has stressed that there were no problems with parts it supplied to other industry customers such as Enbridge Inc. Ezeflow has also said it exceeds safety guidelines.

Where are the parts Kinder Morgan installed?

In July, Kinder Morgan Canada spokesman Andy Galarnyk downplayed the risk of any threat.

“While we believe that there is only a very remote chance that we might have any of the referred to fittings on our system, we are seeking to take the utmost caution and therefore are ensuring a thorough historical review of records is completed before responding to the NEB,” Galarnyk told National Observer on July 6.

However in its assessment to the NEB from Sept. 29, Kinder Morgan identified the 173 pipeline components bought from Canadoil Asia and installed in four different locations, including 57 at a terminal in Edmonton. The remaining 116 parts were spread out at three different locations: the Wolf Pump Station near Edson, Alberta, the Chappel Pump Station near Mt. Robson Provincial Park and Blue River Pump Station, north of Kamloops, British Columbia.

"Trans Mountain has complied with the National Energy Board order," Kinder Morgan told National Observer in a statement. "All subject fittings on the Trans Mountain System have passed testing as part of commissioning. We are awaiting further instructions from NEB."

But one Calgary-based pipeline materials engineer with decades of industry experience, Dennis Maki, raised questions about the quality of Kinder Morgan's review after reviewing the company's submission from September. Maki — who has previously described Canadian pipeline infrastructure as a series of "ticking time bombs" — said that an important section of the company's September submission to the regulator was stamped and approved by an engineer with the wrong type of expertise to properly verify the fittings.

Kinder Morgan and the NEB both declined to comment on questions about the expertise of the engineer who stamped the report.

Meantime, Maki also said the review appeared to have been based on an assumption that the fittings in question on the Trans Mountain line had already been manufactured to meet a pipeline safety code, established by the Canadian Standards Association.

But he argued that a proper review would require input from professional experts with expertise in metallurgical or stress engineering to investigate whether there were manufacturing defects. This is not something that purchasing departments in pipeline companies are well-equipped to verify, Maki explained.

"Purchasing departments and their expeditors have next to no experience with pipeline metallurgy, design, or materials of construction that the pipe, fittings, flanges and valves are manufactured from— let alone any metallurgical fabrication processes, welding, steel heat treatment, and quality control testing," Maki told National Observer.

"Furthermore, the company reporting on tracking of the installation locations and purchase orders (or) traceability information for the fittings places a large disclaimer right at the start of it. I personally do not believe that tracking and indexing of this information alone can be used as a basis for evaluation of the actual technical acceptability of fittings as originally manufactured and then placed into pressure service."

Mount Polley, Lac-Mégantic consequences of poor regulation

Martin Olszynki, a former federal government lawyer who worked in the legal services unit at Fisheries and Oceans Canada, said the general approach to oversight reflected by the NEB — when the regulator comes to see itself being in service to industry — has led to tragedies in Canada such as the Lac-Mégantic runaway train disaster in Quebec in 2013, and the Mount Polley mine disaster in B.C. in 2014, for which the provincial government could be facing criminal charges.

“There is definitely a ‘Canadian approach’ to regulation that stands in contrast to that found in other jurisdictions (including the U.S. — sometimes at least), and that one of its defining characteristics is the more informal relationship between regulators and the regulated community,” said Olszynski, now a law professor at the University of Calgary.

“There is a widely-held view in Canadian regulatory circles (on the proponent and regulator side anyway) that this relationship need not be adversarial and that indeed that would tend to undermine compliance, which is the purported goal of the whole exercise.

“Mount Polley and Lac Mégantic — and the damning reports that followed them — are two examples that should have shaken this dogma but I haven't seen any indication that it has.”

The Liberal government brought in some fresh faces to the regulator by naming four new Board members this week, including an Indigenous lawyer and former senior bureaucrats. It still has plans to “modernize” the NEB before the end of its mandate.

Responses from TransCanada

Here are three questions from National Observer and the full responses from TransCanada spokesman Mark Cooper:

1. Is TransCanada continuing to review and assess the presence of substandard parts on its existing network of infrastructure? If so, what is the status of that assessment?

In regards to the NEB memo from February, TransCanada completed engineering assessments in accordance with Canadian Standards Association Z662, which covers the design, construction, operation, and maintenance of oil and gas industry pipeline systems on the identified pipe fittings, and the conclusion was that the fittings are safe to operate in a pipeline at the NEB licensed maximum operating pressure. The assessment was accepted by the NEB.

2. Would TransCanada agree with the following statements made in the NEB memo regarding the NCC rupture incident: “… the pipeline had a history of substandard material properties. During construction of the project in 2008, two fittings failed pressure testing (one burst, one bulged). A number of fittings were found to have low hardness, but were deemed fit for service by the pipeline operator based on wall thickness. The failure initiated at an elbow that was determined to have low hardness, the wall thickness noted on the data sheet from the manufacturer was incorrect and was never verified by the company or manufacturer.”

The excerpt referred to above from the NEB report is incomplete. The NEB report actually starts with the line, “Although not the direct cause of the of the failure, investigation by the Canadian Transportation Safety Board on the incident revealed that the pipeline had a history …”

TransCanada agrees with Canadian Transportation Safety Board, as described in the NEB memo, that the fittings were not the direct cause of the incident. This incident occurred because the design of the pipeline did not fully take into account the effect of the maximum temperature that the facility would experience during operation. Further, the two fittings that failed pressure testing were not installed in the pipeline and were not related to the line break incident. All fittings that were put in service had successfully passed pressure testing prior to being used for construction.

3. What has TransCanada changed in its practices, since this NCC incident, to improve verification of data sheets and other paperwork that it would rely on in order to ensure the safety and reliability of its pipeline infrastructure?

We’ve taken steps to improve our inspections and audits of third-party suppliers across all of our assets, with the goal of ensuring that pipe fittings supplied to all of our projects meet or exceed our quality standards. These improvements include an increase in design thickness, placing more stringent requirements on heat treatment controls, and completing full manufacturing and quality audits of our large diameter fitting suppliers.

While our system and facilities continue to operate safely, we are constantly working with our vendors to improve the safety of our natural gas pipelines by making continuous improvements in our design, material procurement, construction and testing practices, and lifecycle traceability of components from manufacturing through to construction and operation. When issues are identified TransCanada investigates and looks for opportunity to continually improve our procedures, program and safety of our pipeline system. This enables us to meet or exceed regulations, national standards and industry practices. We use all incidents as learning opportunities to strive even more rigorously toward our goal of zero incidents.

Comments

The NEB has perpetuated the continued operation of an Ontario refined petroleum products pipeline (TransNorthern, TNPI) they know is NOT meeting conditions of numerous NEB safety orders against TNPI; they know TNPI has been operating at pressure exceedances, has had numerous releases, has ordered TNPI to undertake Environmental Site Assessments due to their releases and land contamination, and TNPI has numerous contaminated sites across Ontario that have not been remediated.

Their most recent safety order against TNPI had 2 NEB Board Members dissenting, stating, "TNPI has had six years to comply with numerous Safety Orders issued by the Board, but they have failed to fully comply. We are not confident that yet another similar Safety Order will guarantee that the changes necessary to make the pipeline as safe as possible will actually be made this time. We agree with the Majority that if and when all of the measures described in the Amending Safety Order are implemented, the pipeline system will be as safe as possible. However, until those safety measures are fully implemented, it would have been our preference to have the pipeline system shut down in the interim because TNPI’s current operational controls do not meet the requirements of the National Energy Board Onshore Pipeline Regulations or CSA Z662-15."

The newest safety order calls for a pressure reduction, but allows continued, unsafe operation of this pipeline, DESPITE 2 Board Members' dissent to do so.

Trans-Northern Pipelines Inc. (TNPI) – Safety Orders SG-T217-04-2009, SG-T217-01-2010, and SO-T217-03-2010 – Amending Safety Order AO-001-SO-T217-03-2010 – Overpressure and Pipeline Exposure Incidents

https://www.neb-one.gc.ca/sftnvrnmnt/cmplnc/brdrdr/trnsnrthrn/2016/so-t…

This National Observer article states, "NEB technical staff are expected to have interaction with pipeline companies. Regular dialogue with companies is part of how regulators assure pipeline safety in Canada. NEB staff continue to apply extensive technical expertise in the interest of Canadian pipeline safety and environmental protection."

How does allowing the continued operation of this old (1952), disintegrating TNPI pipeline "assure pipeline safety and environmental protection"?

The last sentence of

http://www.thewhig.com/2013/09/12/part-6-the-lesser-known-pipeline

says TNPI "... try to do all the right things to keep the product in the pipe.”

Right things = Capture of the Regulator?

It's the reason the NEB allows this rotting pipeline to continue operating.

The NEB is a captured regulator, and will continue to be unless the Board is totally dismantled and all processes to regulate pipeline companies (whose sole raison d'être is to make money, AT ALL COSTS), are radically overhauled.

Endemic.

The Alberta Energy Regulator has written it's own indemnity clause within REDA and they are legally immune from any and all of their regulatory actions, or inactions.

"The provincial government took Husky Energy Inc. at its word when the Calgary-based company said it needed more time to explain what caused one of its pipelines to fail east of Maidstone this summer.

Husky was granted a 30-day extension after it told the government late Wednesday that two technical reports — one metallurgic, one geotechnical — being prepared by third-party engineering firms were not finished.

“Our understanding is simply that the reports are not completed,” Doug MacKnight, assistant deputy minister of the Ministry of the Economy’s petroleum and natural gas division, told reporters on a conference call Friday."

http://www.calgaryherald.com/business/province+gives+husky+extension+ex…

All our oil and gas regulators are captured and blatantly so. The only question left to ask, is what can the public, whose health, safety and environment are being put at undue risk and harm, do about it?