Thank you for helping us meet our fundraising goal!

For the past few weeks, I’ve been focusing on electric vehicles (EVs), examining fallacies being embraced by those who don’t believe we can build a cleaner future. This is a key battleground for fossil fuel interests and people who dismiss the seriousness of the climate emergency. Earlier this month, I focused on false claims that EV weight is going to destroy our roads and highways. This week, I address concerns about the environmental impact of mining for battery minerals.

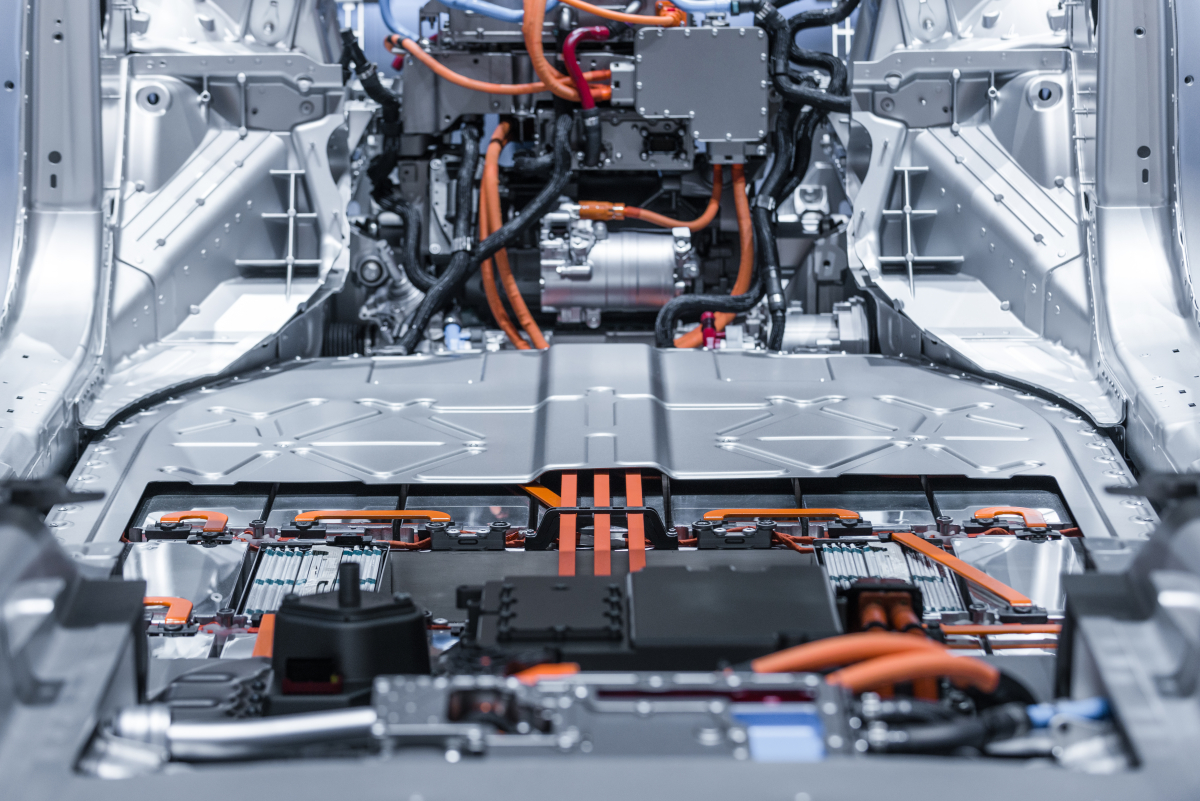

When battery packs replace gas tanks in your vehicle, the automotive industry and its battery suppliers will have taken a major step towards improving the circularity of their business models.

The gas tank and internal combustion engine (ICE) platform is the epitome of waste. Every week or two, we fill our tanks with single-use fuel and burn it to get around. It’s a process that wastes 80 per cent of the energy contained in the fuel while pumping exhaust fumes into our environment.

Everyone understands the efficiency improvements offered by powering an electric motor from a battery, but many people worry that the mining of lithium, cobalt and other minerals used in EV batteries will also damage the environment.

The allure of money, jobs and tax revenues has consistently tempted our society to make poor choices around profit-focused resource extraction. If we simply start building roads into environmentally sensitive ecosystems and excavating massive open pits for lithium supply, then we’ve learned nothing from our past mistakes.

But there is evidence that the rapidly growing battery industry can be much better than the gasoline economy it’s replacing. EV battery minerals are used for the lifetime of the vehicle. Instead of filling our cars with a liquid fuel that must be found and extracted continuously, we can harvest energy from renewable sources and fill our cars with electricity.

As we transition to an electricity-based energy system, the demand for batteries will grow exponentially, but we will also reach a point where recycled battery minerals are the preferred choice of battery manufacturers.

Energy expert Michael Liebreich explains the potential for recycling battery materials: “Suppose your battery has a lifespan of 15 years, and together collection and recovery rates exceed 90 per cent. Then as long as battery energy density improves by 10 per cent every 15 years — and remember, it doubled in the past decade — your initial battery minerals will continue providing the same storage services forever.”

The International Energy Agency (IEA) forecasts battery mineral demand will grow to nearly 12,000 kilotonnes per year by 2040. That will require new mining operations, but it will also reduce the amount of oil we need to extract from the Earth.

According to the IEA, the transport sector accounts for 60 per cent of global oil demand, which was around 100 million barrels of oil per day in 2023. This translates to a transport sector consumption of around 13,000 kilotonnes of non-recyclable fuel per day.

Examining the potential

Engineer and podcaster Rosemary Barnes points out that the minerals in an EV battery are 99 per cent less than the amount of gasoline consumed over the typical lifetime of a vehicle. But rather than argue about which extractive resource industry will do a better job of destroying the planet, let’s have a look at the potential for these industries to clean up their operations.

Australia supplies just over half the world’s lithium using a hard-rock mining process similar to open-pit coal or bitumen mining. It’s energy-intensive.

Chile produces about 30 per cent of world lithium supply using a process that extracts the mineral from underground brine deposits. Brine extraction is more time-consuming, but has about one-third of the CO2 emissions in comparison to open-pit lithium mining.

Direct lithium extraction (DLE) is a third process being developed that promises to reduce water and land use while massively cutting back CO2 emissions. Numerous companies are developing this technology to replace traditional brine extraction methods.

The battery industry is driving innovation to reduce CO2 emissions from lithium mining at the beginning of exponential growth in lithium demand. This is in stark contrast to the fossil fuel industry that is only now striving for net-zero production by 2050, a hollow promise when 70 to 80 per cent of CO2 emissions still occur when the fuel is burned.

Reducing CO2 emissions from the extraction of minerals for lithium-ion batteries is important, but it’s the recycling of those minerals that represents a groundbreaking move towards a circular economic process.

The recycling industry is still in its infancy, but it’s growing quickly. Nevada’s Redwood Materials plans to be producing anodes and cathodes for one million EV batteries annually by 2025. It has established partnerships with major automobile manufacturers Tesla and Toyota.

Although its recycling facility in Rochester, N.Y., has been put on hold due to cost overruns, Toronto-based Li-Cycle has five recycling plants already in operation and is leading the charge for more battery recycling capacity around the world.

In 2022, Hydrovolt launched Europe’s largest EV battery recycling plant and the operation is powered by 100 per cent renewable energy. Hydrovolt is a partnership between Swedish battery manufacturer Northvolt and Hydro, a Norwegian company that produces green aluminum.

In addition to the new ventures trying to capitalize on the growing market for EV battery recycling, all major EV manufacturers (including Tesla, Toyota, Volvo and Volkswagen) have plans for recycling their vehicle batteries. In 2022, Renault Group launched The Future is Neutral, a company that aims to “become the leader in industrial and European scale of the closed-loop automotive circular economy.”

The EV battery industry is an interesting example of a circular economy because there are several stages in its reuse and recycle value chain. For example, companies like B2U Storage Solutions are repurposing end-of-life EV batteries for use in the energy storage industry.

In the very near future, EV battery giga-factories will be surrounded by an ecosystem of suppliers, including companies specializing in different phases of the recycling process. For example, logistics companies will dominate the business of collecting and transporting recovered EV batteries.

First-stage recyclers like Li-Cycle will specialize in the mechanical recovery phase that produces a black mass containing the various minerals in an EV battery. Other companies like Ascend Elements will specialize in separating out lithium, nickel, copper and other minerals from the black mass.

The transition to electric vehicles is creating new businesses and careers that can exist in any country in the world, unlike the fossil fuel industry where a few resource-rich regions enjoy all the benefits. Battery manufacturing is already a more distributed industry and recycling will reduce dependency on countries with rich lithium deposits.

The electrification of the transport sector is a long overdue reboot of an industry that emerged in 1908 with the Model T Ford. This time, there is more thought going into reducing the impacts of resource extraction and efforts are being made to build a circular economy, which eliminates waste and reduces the amount of mining required. It’s a game-changing revolution.

Rob Miller is a retired systems engineer, formerly with General Dynamics Canada, who now volunteers with the Calgary Climate Hub and writes on behalf of Eco-Elders for Climate Action, but any opinions expressed in his work are his own.

Comments

Thanks for debunking the false narratives of the MSM about EV.

The propaganda against EV peddled by MSM is very dishonest and devious, it has managed to delay the transition and disrupt the free enterprise among the suppliers of different sources of energy and different powertrains for transport.

Edward Bernays, the king of propaganda, could not have done better.

We know now that it is cheaper to own and certainly run an EV or cheaper to replace dirty fossil fuel energy by Renewal Energies.

If you have the budget to buy a new car, you can now buy a Tesla for less than the average cost of new cars. If you don’t have that money well this is a different problem and I sympathize.

Don't take my words for it, go see:

https://www.tesla.com/en_ca

You can compare an EV with a Hydrogen vehicle because they are both zero emissions, but any comparison between an ICE car with any EV is very dishonest until we see an ICE car with zero emissions.

Can we just imagine the weight, the range, the look and the cost of a zero-emission ICE car?

A diesel car can be compared with a gas car and see for instance which one kills the least number of people every year with their toxic fumes or which one increases the cost of our healthcare system the most or which heavy fossil SUV destroys out roads the least with their big tires and leaking petrol liquid. See, these are comparable.

But by allowing an ICE car to not be zero emission in the comparison with an EV, a lot of inconvenient variables do not show in the equation and this is a distortion of reality.

As if to say, we have spewed the toxic fumes of tailpipes in the atmosphere as an open sewer for the last century, what is wrong with that, it’s free?

Do MSM think that if we treat the planet as a potato to put in the oven we could feed the world?

I am waiting for the next generation of lower priced EV's Tesla and other companies are looking to move into that market since the Chinese are there already. $20,000 to $30,000 is a reasonable price point to get me into a EV and it is not that far away. I really enjoyed the article taking apart the disinformation about the future of EV's. The Oil industry for gasoline and diesel must be spending billions to try to save their fossil fuel industry.

An excellent article. Thank you.

One of the key phrases here is "circular economy." The evidence is accumulating to show that EVs will become a moving accumulation of nearly total recycled materials.

The link between EV battery development and grid storage is already very strong and evolving fast. Tesla batteries (CATL or BYD battery packs are packaged under the Tesla moniker) are the are primary components in Australia's recently very rapid ramping up of renewable power. Tesla's safe battery chemistry using lithium, iron and phospate is the central battery component make up in the largest offshore wind project in the world currently coming onstream in Scotland.

The fact that the base battery materials in EVs and much larger battery arrays now used in the grid are 100% interchangeable and recycleable indicates the huge potential to speed up the transition as the technology matures and prices decrease.

As an urbanist over the past 40 years I fully recognize the superiority of walkable communities and transit orientation over car dependent cities. This doesn't eliminate EVs, especially the 30% of traffic that moves goods on urban roads, such as food deliveries to grocery stores.

Defeating car dependency takes generations, literally because it requires rebuilding cities from the inside. This doesn't mean the overall population of cars in our cities will not decrease, often dramatically (world car dependency already peaked in the 2015-18 period). It means that the ever reducing numbers of cars should not continue to perpetuate oil dependency. That cord must be severed ASAP.

EVs immediately eliminate Scope Three emissions in transport, the biggest dark cloud of them all. It's only a matter of time before emissions from mining and production are electrified with very low emission profiles as well. And now, battery component recycling (electrified, of course) is already developing in two directions in great harmony: transport and the electrical grid. In my view, grid storage will eventually dominate.

So, if presented a multiple choice question, like

What is important to act on as the transition continues to evolve:

1. Walkable cities with great transit and human scaled urban design;

2. EVs;

3. Both?

The answer is #3, both, until such time #1 has been fully built out.

Non-lithium grid battery chemistries are fast evolving too. Zinc bromide and vanadium flow batteries as well as iron air battery packs are all appearing at large scales in several nations. These batteries offer ideal power storage and grid stabilization options for renewables.

Thanks for your input as an urbanist. Here in Québec we have this false narrative about incentives going to EV would be better used to promote public transportation.

It sounds pretty but it is very naive to think that this money would be used to improve public transport or better urbanism.

Where has the EV incentives money been directed to, after Ontario Conservatives cancelled the best EV incentive program in Canada?

Who is peddling the information that EV owners are against good urbanization? We like walking, biking and intelligent urbanization too.

Bad urbanization started before the EV was a subject of conversation.

If we are serious about reducing the number of cars, we have to go EV. It is a computer on wheels, it can be programmed to Full Self-Driving. Tesla is redefining what a car is with its FSD which will lead to robotaxi. Robotaxi will make Transport as a Service TaaS a reality and many people will question the wisdom of owning a car.

I think the jury is out on robocars, and will be out for a long time. The jury has already made EVs as home power storage a reality. Fleets of EVs also collectively offer the opportunity to provide massive battery input to the grid when demand peaks. This is done through net metering with the regional utility when plugged in and placed under user digital control to control charging and discharging cycles. Selling power to the grid at peak use rates could offset the user's costs, perhaps even generate a profit over time.

Excellent, rational info. Too bad our Provincial leaders and Conservative leader of opposition haven't the guts to buy into the future and are wasting so much time and energy trying to fight the the equivalent from horses to gasoline vehicles or from coal to diesel on the railways. What happens to the lead acid battery in your car or lawn tractor? It is recycled and the material reused, and it lead acid vs much more valuable modern materials.