Support strong Canadian climate journalism for 2025

Carbon capture is touted as a key climate-fighting technology by government and industry alike. Canada’s climate plan depends heavily on carbon capture to reduce greenhouse gas emissions from industrial processes, including oil and gas production, but the technology has yet to be perfected and there are concerns that relying on it will lock-in fossil fuel use.

As part of a new Canada’s National Observer series breaking down climate basics, we delved into some common questions about this contentious carbon-cutting tech. Here is everything you need to know about carbon capture.

What is carbon capture?

Carbon capture is a technology that prevents carbon dioxide released from industrial processes from reaching the atmosphere and warming the planet. When CO2 — a long-lasting greenhouse gas — is emitted by a natural gas processing facility, coal or gas-fired power plant, or fertilizer, cement, chemical or steel production facility, this technology captures it right at the source so it can be compressed into a liquid-like form. Once compressed, the captured CO2 can be transported by pipeline to be used or stored permanently. If the CO2 is stored permanently, the process is referred to as carbon capture and storage (CCS). If it’s used first, it’s called carbon capture, utilization and storage (CCUS).

Carbon capture is often confused with a technology called direct air capture, but the two are completely different. Direct air capture pulls CO2 out of the atmosphere, as opposed to capturing it directly from an industrial source.

How does carbon capture work?

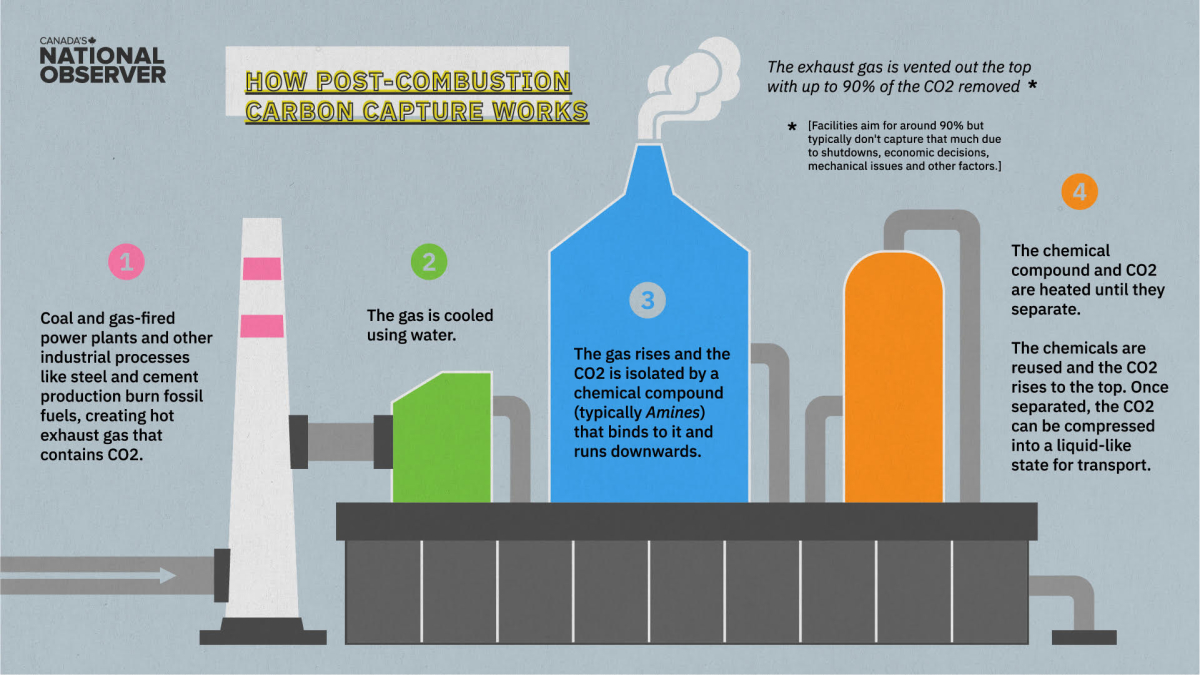

One of the three most common types of carbon capture technology removes CO2 after fossil fuels are burned and is called post-combustion carbon capture. This technology can be fitted onto existing power plants and many industrial facilities.

When fossil fuels are burned, hot exhaust gas containing CO2 and other pollutants is taken directly from the smokestack and cooled down using water. The exhaust gas then rises up through a large tower as a chemical compound called amines that binds to CO2 molecules and runs downwards, taking the CO2 with it. This is said to remove up to 90 per cent of the CO2 from the exhaust gas, which vents out the top of the tower. The amine-CO2 solution that remains is heated and separates the amines from the CO2 so the former can be reused and the latter can be compressed and transported.

There are two other main approaches for carbon capture. Natural gas processing plants separate CO2 from the gas before it is burned with pre-combustion technology. Oxy-fuel combustion technology uses pure oxygen to combust fuel, which creates waste gas composed of water vapour and CO2 that can be captured.

What can carbon capture be used for?

In Canada, carbon capture technology is used for coal power, hydrogen production and throughout the oil and gas sector.

Saskatchewan is home to Boundary Dam, the only coal-fired power station in the world using carbon capture on one of its units as of February 2023. Alberta has the world’s second hydrogen production plant outfitted with carbon capture, and another planned for 2024.

The province also has a 240-kilometre pipeline that collects carbon captured from the Nutrien fertilizer plant and Sturgeon heavy oil refinery in Redwater, Alta., and transports it to central Alberta to be injected into depleted oil and gas reservoirs so companies can extract more oil.

This process — called enhanced oil recovery — is by far the most common use of captured CO2. Almost all the CO2 captured at Boundary Dam is used for enhanced oil recovery. In fact, an estimated 80 to 90 per cent of all the CO2 humans have captured in the last 50 years has been used to squeeze more oil out of old wells, according to a 2022 report by the Institute for Energy Economics and Financial Analysis (IEEFA). Selling CO2 for this purpose allows companies to recoup the high costs of deploying carbon capture technology in the first place.

As Canada strives to meet its climate goals, the federal government is counting on carbon capture technology to cut down on CO2 pollution from the production — but not the use — of oil and gas. In Budget 2022, the federal government proposed an investment tax credit program worth an estimated $8.6 billion to help companies cover up to 50 per cent of the cost of investing in CCUS equipment that will be used for storing CO2 underground or injecting it into cement.

The investment tax credit will apply retroactively from Jan. 1, 2022, onwards after the legislation receives royal assent. Finance Canada told Canada’s National Observer in a statement that “the legislation to implement the measure will be tabled in due course.”

Importantly, the investment tax credit does not count enhanced oil recovery as an eligible use of CO2 — though that will not discount some projects from receiving the credit.

When CO2 is not used but rather stored straight away, it is compressed into its liquid-like form and injected into geological formations called saline aquifers, typically more than one kilometre underground. These formations are a layer of porous rocks saturated with salty water.

By forcing extra oil out of mature wells, the enhanced oil recovery process adds more CO2 to the atmosphere than is captured.

There are a handful of less common uses for captured CO2 — for example, injecting it into concrete. CO2 can also be turned into various fuels, but this — and niche uses like carbonation for drinks — immediately puts the CO2 back in the atmosphere.

In some sectors — like steel and cement manufacturing — it is very difficult to reduce emissions and carbon capture is one of the best options to decarbonize, according to the International Energy Agency. We can replace coal, oil and gas with clean energy, but steel and cement are both very energy-intensive to produce and are integral materials for vehicles, buildings and most infrastructure. For the most part, this is not being done at scale, yet: Abu Dhabi is home to the world’s only operational steel sector carbon capture project, and the first cement plant using carbon capture is expected to be operational in 2024.

How effective is carbon capture?

Carbon capture technology is frequently heralded as being able to capture up to 90 or 95 per cent of CO2 that passes through it. The catch is these target capture rates are aspirational and most projects fail to deliver consistently.

A recent analysis of 13 carbon capture projects, accounting for more than half of capture capacity from operating projects worldwide, found that 10 of these facilities underperformed and several failed entirely.

While the Quest CCS facility in Alberta has been close to hitting its capture goals, a 2022 report by Global Witness found the hydrogen plant has emitted more CO2 than the technology captures and has an average capture rate of less than 50 per cent.

Boundary Dam Unit 3 in Saskatchewan was designed to be able to capture 90 per cent of the emissions from one of its turbines, or approximately one million tonnes of CO2 per year. But in reality, it has been capturing just over 615,000 tonnes per year, according to IEEFA analysis based on SaskPower’s data.

Some common reasons carbon capture technology underperforms and allows CO2-laden exhaust gas into the atmosphere include maintenance shutdowns, mechanical problems and other outages due to the high volume of power needed to run the technology.

In many cases, CO2 stored through enhanced oil recovery is thought to be permanent, if sealed properly, according to the most recent IPCC report. However, unlike dedicated underground storage sites, enhanced oil recovery operations typically don’t assess the area to make sure it's suitable to store CO2 or monitor the site for leaks after the fact.

Between 78 and 98 per cent of CO2 stored in geological formations is estimated to remain safely stored for 10,000 years, according to a 2018 study published in the science journal Nature.

Still, big questions remain about who will be responsible for monitoring CO2 injection sites in the long term to ensure CO2 doesn’t leak into the atmosphere. There are concerns the burden will fall to taxpayers, as has happened with Canada’s abandoned oil and gas wells.

Fossil fuel companies and lobby groups laud carbon capture as the answer to the industry’s outsized impact on climate change, insisting the technology will keep Canadian oil relevant and competitive in international markets despite the global energy transition.

But the technology does nothing to address the vast majority of the oil and gas sector’s CO2 emissions, which occur when we burn fossil fuels to drive cars and heat buildings, for example.

Carbon capture technology is also very expensive. The federal government’s investment tax credit aims to help alleviate those costs and other federal programs have doled out hundreds of millions for projects. Alberta and Saskatchewan have also helped foot the bill with generous subsidies for CCUS projects in their jurisdictions.

Is carbon capture a viable climate solution?

The answer to this question depends on who you ask.

Canada's fossil fuel sector and most levels of government say carbon capture is an important part of the national and international climate toolkit, while its critics warn it is a costly distraction from solutions like wind and solar, and risks locking in fossil fuel use for decades to come.

The world’s leading climate authority — the Intergovernmental Panel on Climate Change — says there is a role for carbon capture as governments try to slash emissions and limit global warming to the Paris Agreement target of no more than 2 C. But its latest report also found CCUS and CCS technology is one of the most costly and least effective options to address climate change.

The world’s currently operating carbon capture projects are capable of capturing just over 40 million tonnes of CO2 per year, or roughly 0.1 per cent of global emissions, if they all perform as advertised. Domestically, these expensive projects only capture about 0.05 per cent of Canada’s greenhouse gas emissions.

Canada’s oil and gas sector made up 27 per cent of the country’s total emissions in 2020, according to the federal government. This sector is responsible for more planet-warming pollution than any other, but industry groups and companies maintain that carbon capture technology can slash emissions and allow oil and gas production to continue decades into the future.

The Pathways Alliance has a plan to outfit as many as 20 oilsands production facilities with carbon capture technology and construct a 400-kilometre pipeline to transport captured CO2 to a proposed storage hub near Cold Lake, Alta. This massive carbon storage hub would require an estimated $16.5 billion of investment by 2030, according to the alliance, which represents Canada’s largest oilsands producers.

But carbon capture projects that aim to increase or prolong fossil fuel production and use are not a climate solution and result in far more emissions than they capture, climate advocates and some scientists and experts argue. Government support for carbon capture to address emissions from fossil fuel production essentially amounts to a fossil fuel subsidy, many say.

In a scenario where the world achieves net-zero emissions by 2050, 34 times more carbon capture infrastructure needs to be built by the end of this decade, based on figures from the International Energy Agency’s 2022 World Energy Outlook.

Comments

If the oil and gas companies think carbon capture is a good idea then it clearly isn't. An ineffective, expensive boondoggle to let these companies continue to extract oil and gas instead of switching to other energy sources.

Thanks for laying out the realities of carbon capture as an ineffective tool to address emissions reduction that relies on magical thinking and impossible math. Firstly, 'Pathways Alliance' has a plan to reduce emissions related only to their collective production of crude. This does not include Scope 3 emissions from consumer use of oil products - gasoline, diesel etc which account for 80% of that emission pathway. Therefore, even were 'Pathways Alliance' to achieve a 25% reduction in production-related emissions, this would equate to only 5% of overall CO2 emissions reduction from the overall pathway. Natasha rather modestly states that CCUS infrastructure would have to increase a mere 34 fold by 2030 (just over 2500 days from now) to support the IEC's ambitious 'Net Zero Emissions' scenario. But, in absolute terms, that's only about 1.4 GT of CO2 based on present levels of emissions capture. And, ironically, achieving this ultra low emissions scenario requires global sales of zero emissions vehicles to reach 60% by 2030, no new ICE vehicles by 2035 and no new ICE trucks by 2045. The scenario also sees global emissions fall from around 40 GT now to 5 GT by 2040 due to mass electrification etc. The question is - how on earth can we possibly achieve all this if we continue to throw taxpayer subsidies at oil & gas producers to perpetuate fossil fuel production when this direction will quite certainly lead to runaway global temperature rises? CCUS is not a mainstream solution - it is simply a smokescreen.

Like taking a daily multivitamin in the hope you can continue a two-pack-a-day habit without any health risk. Industry (who pitched it) and government (who drank the Cool Aid) have both extolled the virtues of CCUS for roughly 20 years, and yet all they can show for it is a dismally low rate of implementation and performance well below spec. Beware anyone attempting to sell you some magic beans.

Nice analogy.

Why should the public pay a nickel for the oilsands industry's fake climate solutions? What ever happened to polluter pay? The free market?

Why are we paying mega-wealthy oil companies to clean up their act? Clean-up, reclamation, and emissions reduction are all standard costs of doing business. Why should taxpayers be on the hook for industry's business expenses? What ever happened to free enterprise? Polluter pay? Why don't we pay for Cenovus Energy's pencils and paper too? Poor CEO Alex Pourbaix probably needs a new jet as well.

A delay tactic — not a climate solution. Not just doomed to fail, but designed to fail. Its purpose is to provide political cover for O&G expansion and new projects. To perpetuate the use of fossil fuels. Fossil fuels for longer means more emissions, not less.

The Pembina Institute's reports cast doubt on CCS's efficacy in the oilsands:

The Pembina Institute acknowledges that in the oilsands sector "most CO2 is emitted in low concentration streams, and the efforts to capture it will be challenging and expensive."

CCS captures a tiny fraction of emissions at high cost.

Where CO2 sources are small or diffuse, e.g., in the oilsands apart from upgraders, CCS is not economical or practical.

The Pembina Institute estimates that "full deployment of CCUS in all high-concentration streams could result in a decrease of c 7 Mt CO2e annually, which equates to 8% of total oilsands emissions."

Tens of billions of public dollars out the window to capture a small fraction of total upstream emissions. Of course, reducing upstream emissions does nothing to cut the 80–90% of emissions generated from a barrel of oil downstream at the consumer end.

CCS merely perpetuates the oil industry. Fossil fuels for longer means more emissions, not less.

"Carbon capture industry likely to fail, according to analysis' (CTV, Sept. 7, 2022)

"Carbon capture and storage projects are more likely to fail rather than succeed, according to a new industry assessment by the Institute for Energy Economics and Financial Analysis (IEEFA).

"The study found 10 of 13 CCS flagship projects missed its targets, 7 underperformed, 2 failed and one mothballed.

"'A lot of government money and a lot of private money has been poured into this industry and it's still producing projects that don't work.'

"… even successful projects like the Quest CCS project in Alberta use a lot of energy.

"'We worked out that about 21% of supposed carbon savings were actually used up in actually collecting the CO2.'"

"Yet even RBC admits that a rapid deployment of [carbon capture] technology isn't very likely.

"'It's pricey, slow to build, adds costs, relies on complex engineering, and sometimes fails to capture or store emissions effectively,' RBC explains in the April report (2022). 'The technology also needs to be tested in large-scale settings. As yet, there are no major plants that capture CO2 from the combustion of natural gas, which is the primary application for the oilsands.'

"But there is one clear advantage to be gained from carbon capture and storage — it buys the oil and gas industry time.

"To climate experts like Richard Brooks, director of the climate finance program at the advocacy group Stand.earth, RBC's current climate strategy is merely an excuse to keep fossil fuel profits flowing as long as possible.

"'RBC says it wants to achieve net zero by 2050,' he said. 'But you scratch slightly below the surface, not very far, and you can see that they have no plan to get there.'"

"What Haunts Canada's Banks? A Green Pivot from Oilsands" (The Tyee, 4-May-22)

"CCS carries the promise of business as usual with a minimum of inconvenience to the consumer. Under the promise of CCS, we can keep on burning massive amounts of fossil fuels.

"To implement CCS on the scale necessary to combat global warming will be a 'large, massive, daunting task.' The scale is staggering.

"However, the effort necessary would not be merely 'big' but so immense as to be impractical, according to Vaclav Smil, an energy expert at the University of Manitoba.

"Smil, a self-described 'intellectual agent provocateur,' has declared 'carbon sequestration is irresponsibly portrayed as an imminently useful option for solving the challenge (of global warming).'

"Smil has estimated that simply capturing a fraction of global emissions and sequestering them in one year would require moving volumes of fluid CO2 on a scale similar to the worldwide transportation of oil, a massive enterprise requiring tens of years and trillions of dollars.

"'Beware of the scale,' he said. 'Sequestering a mere 1/10 of today's global CO2 emissions (about 3 billion tonnes) would thus call for putting in place an industry that would have to force underground every year the volume of compressed gas larger than or ... equal to the volume of crude oil extracted globally by the petroleum industry whose infrastructures and capacities have been put in place over a century of development. Needless to say, such a technical feat could not be accomplished within a single generation.'

"...oilsands companies have backed away from CCS, realizing the technology will likely not help the industry reduce CO2 pollution because the oilsands have too many diffuse emission sources. In 2008, the CBC obtained internal federal briefing notes that explained that CCS is better suited to large single-point industrial sources of CO2 such as coal-fired plants. 'Only a small percentage of emitted CO2 is 'capturable' since most emissions aren't pure enough. Only limited near-term opportunities exist in the oilsands and they largely relate to upgrader facilities.'

"… any success may ultimately be limited to a relatively few projects due to cost, liability, technology, scale and public skepticism. CCS may turn out to be another costly Faustian bargain and classic technical fix.

"Instead of buying us time to find alternate sources of clean energy, CCS is buying politicians' time to avoid making tough, unpopular decisions. The allure of CCS as a political fix threatens to divert resources from energy efficiency and delay more durable reforms.

"In sum, the marriage of a brave new technology with a political fix for an immediate climate problem could have negative long-term consequences for Canadian taxpayers and water drinkers without stabilizing the climate."

"Burying CO2: Fix or folly?" (Edmonton Journal, 2009)

"Lessons from Australia show CCUS is about capturing public opinion and public finances, not carbon" (National Observer, April 6th 2022)

"The principal purpose of CCUS has never been to tackle the climate crisis. Instead, CCUS serves to align public opinion and government policies with the fossil fuel industry's plans for unrestricted expansion under the cover of 'net-zero by 2050' rhetoric."

As per 2022 Pembina Institute "Getting on Track" report, heaters and boilers generate low-concentration CO2 streams. The only practical CCS application in the oilsands is hydrogen production plants associated with upgraders:

The cost and effectiveness of CCS depends on several factors, including the size of the waste stream and the CO2 concentration. For carbon capture to be economical/practical, CO2 concentration and volume need to meet minimum requirements. It is more expensive and less worthwhile to try to capture CO2 from small or diffuse CO2 sources. In case of many small or diffuse CO2 sources, total emissions may be high, but CCS is not economical or practical. Low-concentration CO2 streams incur high compression costs. Distributed in situ projects (over a wide area) also incur high transportation costs. Thus, in situ projects are at a double disadvantage.

In the oilsands, upgrader hydrogen plants (hydrogen production from natural gas) have high-CO2 (16-18%) streams. In situ projects (natural gas combustion --> steam generation: steam boilers and cogeneration plants for SAGD; large gas-fired turbines, boilers, and heaters) have low-concentration (4-8%) CO2 streams.

CCS is practical only for upgrader hydrogen production plants, but much more expensive and less likely for in situ projects. CO2 from small or diffuse sources like vehicles, heavy diesel powered machinery and trucks, tailings ponds, and mine deposits cannot be captured at all.

One of many concerns I have in discussions about CCS is there is commonly no mention of where some/all of the energy comes from. For instance, in the schematic "How post-combustion carbon capture works", the last stage (4) states "The chemical compound and CO2 are heated until they separate". What is the source of the energy for this heating? And why is this 'glossed over'? Also, to quote, "Some common reasons carbon capture technology underperforms and allows CO2-laden exhaust gas into the atmosphere include maintenance shutdowns, mechanical problems and other outages due to the high volume [sic] of power needed to run the technology." Again, there is no explanation of the source(s) of the energy required.

Just as in constructive discussions of the energy required to mine/manufacture material for EV batteries and the EVs themselves, we would all benefit from at least a modicum of effort to deal with similar issues for CCS -- what are the sources of the required energy? I wouldn't be surprised if it isn't more fossil fuels. But maybe they use (could use) heat pumps (again, we would need to know the source of the energy to run the heat pumps) to capture heat from Stage 2 of the schematic, which could be used in Stage 4. But is that the case? We don't know from this article.

I've learned in reading about anything to do with technological solutions to greenhouse gas problems is always question what the source(s) of the energy is(are). As in the case for bitumen sands, most of it comes directly or indirectly from the production/combustion of more fossil fuels.

Good point.

While I appreciate efforts to inform, this article could have been more effective by being more direct as well as more precise through word choice.

“…the technology has yet to be perfected and there are concerns that relying on it will lock-in fossil fuel use.”

How about: “…the technology, though having been in use -- and under further development -- for more than 20 years, still has but a miniscule impact on the reduction of anthropogenic CO2 emissions, and there are...”

“Carbon capture is a technology that prevents carbon dioxide released from industrial processes from reaching the atmosphere and warming the planet.”

Well, carbon capture, itself, is agnostic as to its CO2 source. Direct air capture is also carbon capture. (See below)

“If it’s used first, it’s called carbon capture, utilization and storage (CCUS).”

“Used first” suggests something happens subsequently. Does anything happen subsequently?

“Carbon capture is often confused with a technology called direct air capture, but the two are completely different.”

An apple and a treatise on toenail fungus are completely different. Direct air capture is a form of carbon capture. (See above)

“By forcing extra oil out of mature wells, the enhanced oil recovery process adds more CO2 to the atmosphere than is captured.”

How? Are you implying ‘net’ life-cycle emissions assuming the recovered oil is subsequently combusted (rather than otherwise used)? The conclusion is not clearly arrived at.

“For the most part, [CCUS in cement manufacture]is not being done at scale, yet:”

This wording leaves the impression that “something else” _is_ being done at scale. That something else is certainly not industrial CCS.

It's difficult to find a single internet source which provides a current, concise and objective explanation of CCUS, sadly. Otherwise, I’d suggest CNO simply provide a link to it, rather than reinvent the wheel.

In lieu, here’s a link to a current (last month) review/introduction from Nature journal of a recent study regarding broader CDR (Carbon Dioxide Removal). So, don’t equate its CDR reference, and statistics, to apply to industrial CCUS only, as does this CNO article.

https://www.nature.com/articles/d41586-023-00180-4

Also, keep in mind that CCUS is very expensive (and as mentioned elsewhere cannot be used to capture downstream emissions from, e.g., transportation). Direct air capture is, currently, outrageously costly.

Sorry, I should practice what I preach!

I said: "So, don’t equate its CDR reference, and statistics, to apply to industrial CCUS only, as does this CNO article."

Should have said: "So, while this CNO article speaks only to industrial CCUS, the Nature reference speaks to the broader mechanisms that remove/prevent atmospheric CO2."

Hopefully that's clearer.